Galvanized Steel Pipe

Category:

Galvanized Steel Pipe

Keywords:

Galvanized Steel Pipe

PRODUCT DESCRIPTION

Galvanized Steel Pipe Description

Galvanized pipe Galvanized steel pipe, also known as galvanized pipe, is divided into two kinds of hot dip galvanized and electro galvanized. The hot-dip galvanized layer is thick, the coating is uniform, the adhesion is strong, and the service life is long. Zinc is commonly used to galvanize or coat these metal tubes. The galvanizing process for steel pipes involves immersing the metal pipe in a bath containing 450 degrees Fahrenheit molten zinc. After a few minutes, the hot-dip galvanizing process is complete.

Product Parameters

Product Name | Galvanized Steel Pipe |

Standard | ASTM A53, BS1387-85, GB/T3091-08, DIN2440, JIS-G3444, EN10240, EN10255, etc. |

Grade | Q195, Q215, Q235, Q345, S235JR, S275JR, STK400, STK500, etc. |

Zinc Layer | Hot Galvanizing: 60g/㎡-275g/㎡ |

Precoated Galvanizing: 80g/㎡-275g/㎡ | |

Outer Diameter | Round Tube: 17mm-273mm |

Square Tube: 15mm*15mm-400mm*400mm | |

Rectangular Tube: 10mm*20mm-200mm*400mm | |

Wall Thickness | Round Tube: 0.6mm-12mm |

Square Tube: 0.6mm-20mm | |

Rectangular Tube: 0.6mm-20mm | |

Length | 2m-5.8m,6m,12m, Support customization |

Scope of Application

After galvanizing, these metal pipes can be used for many different purposes, such as: water pipes, gas pipes, chemical pipes, sanitary pipes, HVAC pipes and industrial pipes. They are often used in building construction and the development of water supply systems because they are very durable and last longer than other types of pipes such as PVC (polyvinyl chloride) or copper pipes.

| Nominal Bore & Class | Outside Diameter (OD) | Wall Thickness (T) | Nominal mass of steel tube | Sockets | |||||||

| Max | Min | Plain End | Screwed & Socketed | Min OD | Min Length | ||||||

| mm | inch | mm | mm | mm | swg | kg/mtr | mrs/mt | kg/mtr | mtrs/mt | mm | mm |

| 15L | 0.5 | 21.4 | 21 | 2 | 14 | 0.947 | 1056 | 0.956 | 1046 | 27 | 37 |

| 15M | 0.5 | 21.8 | 21 | 2.6 | 12 | 1.21 | 826 | 1.22 | 820 | 27 | 37 |

| 15H | 0.5 | 21.8 | 21 | 3.2 | 10 | 1.44 | 694 | 1.45 | 690 | 27 | 37 |

| 20L | 0.75 | 26.9 | 26.4 | 2.3 | 13 | 1.38 | 725 | 1.39 | 719 | 32.5 | 39 |

| 20M | 0.75 | 27.3 | 26.5 | 2.6 | 12 | 1.56 | 641 | 1.57 | 637 | 32.5 | 39 |

| 20H | 0.75 | 27.3 | 26.5 | 3.2 | 10 | 1.87 | 535 | 1.88 | 532 | 32.5 | 39 |

| 25L | 1 | 33.8 | 33.2 | 2.6 | 12 | 1.98 | 505 | 2 | 500 | 39.5 | 46 |

| 25M | 1 | 34.2 | 33.3 | 3.2 | 10 | 2.41 | 415 | 2.43 | 412 | 39.5 | 46 |

| 25H | 1 | 34.2 | 33.3 | 4 | 8 | 2.93 | 341 | 2.95 | 339 | 39.5 | 46 |

| 32L | 1.25 | 42.5 | 41.9 | 2.6 | 12 | 2.54 | 394 | 2.57 | 389 | 49 | 51 |

| 32M | 1.25 | 42.9 | 42 | 3.2 | 10 | 3.1 | 323 | 3.13 | 319 | 49 | 51 |

| 32H | 1.25 | 42.5 | 41.9 | 4 | 8 | 3.79 | 264 | 3.82 | 262 | 49 | 51 |

| 40L | 1.5 | 48.4 | 47.8 | 2.9 | 11 | 3.23 | 310 | 3.27 | 306 | 56 | 51 |

| 40M | 1.5 | 48.8 | 47.9 | 3.2 | 10 | 3.56 | 281 | 3.6 | 278 | 56 | 51 |

| 40H | 1.5 | 48.8 | 47.9 | 4 | 8 | 4.37 | 229 | 4.41 | 227 | 56 | 51 |

| 50L | 2 | 60.2 | 59.6 | 2.9 | 11 | 4.08 | 245 | 4.15 | 241 | 68 | 60 |

| 50M | 2 | 60.8 | 59.7 | 3.6 | 9 | 5.03 | 199 | 5.1 | 196 | 68 | 60 |

| 50H | 2 | 60.8 | 59.7 | 4.5 | 7 | 6.19 | 162 | 6.26 | 160 | 68 | 60 |

| 65L | 2.5 | 76 | 75.2 | 3.2 | 10 | 5.71 | 175 | 5.83 | 172 | 84 | 69 |

| 65M | 2.5 | 76.6 | 75.3 | 3.6 | 9 | 6.42 | 156 | 6.54 | 153 | 84 | 69 |

| 65H | 2.5 | 76.6 | 75.3 | 4.5 | 7 | 7.93 | 126 | 8.05 | 124 | 84 | 69 |

| 80L | 3 | 88.7 | 87.9 | 3.2 | 10 | 6.72 | 149 | 6.89 | 145 | 98 | 75 |

| 80M | 3 | 89.5 | 88 | 4 | 8 | 8.36 | 120 | 8.53 | 117 | 98 | 75 |

| 80H | 3 | 89.5 | 88 | 4.8 | 6 | 9.9 | 101 | 10.1 | 99 | 98 | 75 |

| 100L | 4 | 113.9 | 113 | 3.6 | 9 | 9.75 | 103 | 10 | 100 | 124 | 87 |

| 100M | 4 | 115 | 113.1 | 4.5 | 7 | 12.2 | 82 | 12.5 | 80 | 124 | 87 |

| 100H | 4 | 115 | 113.1 | 5.4 | 5 | 14.5 | 69 | 14.8 | 68 | 124 | 87 |

| 125M | 5 | 140.8 | 138.5 | 4.8 | 6 | 15.9 | 63 | 16.4 | 61 | 151 | 96 |

| 125H | 5 | 140.8 | 138.5 | 5.4 | 5 | 17.9 | 56 | 18.4 | 54 | 151 | 96 |

| 150M | 6 | 166.5 | 163.9 | 4.8 | 6 | 18.9 | 53 | 19.5 | 51 | 178 | 96 |

| 150H | 6 | 166.5 | 163.9 | 5.4 | 5 | 21.3 | 47 | 21.9 | 46 | 178 | 96 |

Packing and delivery

Our products are exported to more than 30 countries including Africa, Sri Lanka, Turkey, Vietnam, Laos, Brazil, Thailand, the Middle East, the United Arab Emirates, Morocco, Spain, the United States, New Zealand, and Iran.

Customer visit

Xintong Nonferrous Metals (Guangdong) Co., Ltd. operates in multiple countries and regions, including Asia, Europe, and North America, and has established long-term, stable cooperation with hundreds of clients worldwide. Through our strong international procurement and sales network, we are able to flexibly respond to changes in the global market and offer more competitive products and prices.

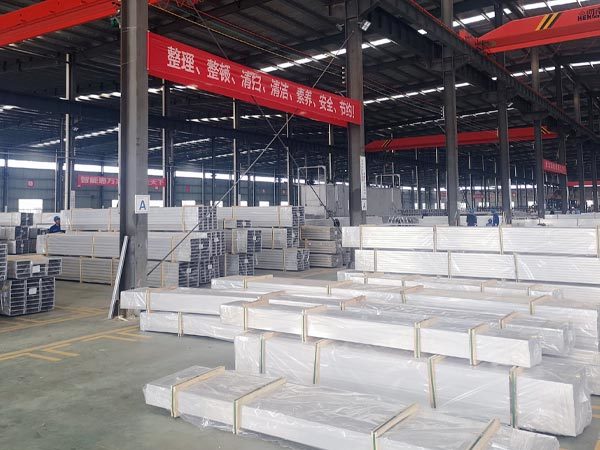

FACTORY

The company is equipped with a complete range of advanced equipment, mainly producing various products including carbon steel, stainless steel, galvanized steel, steel bars and wire rods.

Backed by strict full-process quality control, innovative production technologies and sufficient inventory, it can accurately meet the diversified and customized procurement needs of global customers.

APPLICATION

These products are widely used in key industries such as construction, energy, machinery, shipbuilding, petrochemicals and pressure vessels. With strict full-process quality control, innovative production technology and sufficient inventory, the company can accurately meet the diversified and customized procurement needs of global customers.

HONOR

WHY CHOOSE US?

High quality product and good price.

Good Pre-sale、on sale and after sales service.

Short delivery time.

Exported all over the world, with rich experience.

The products can be made completely according to the customer's requirements, and we have our own factory.

FAQ

Q1: What is your MOQ?

A: Usually our MOQ is one container, but it is different for some items, please contact us for details.

Q2:What is your terms of payment?

A:We usually accept T/T in advance, L/C for large sum.If you prefer other payments terms, please discuss.

Q3:What is your delivery time?

A:For products in stock, we can ship it within 7 days after receiving the deposit. For custom order, production time is 15-30 workdays after received the deposit.

Q4:How could you guarantee your products?

A:Mill Test Certification is supplied with shipment, We also accept and support the third-party inspection.We also could issue the warranty to customer to guarantee the quality.

Q5: Will all costs be clear?

A:Our quotation is easy to understand and will not incur any additional costs.

Q6:Can you give warranty of your products?

A:Yes, we extend a 100% satisfaction guarantee on all items. Please feel free to feedback immediately if you are not pleased with our quality or service.

RELATED PRODUCTS